Supply Chain: The True Game of Risk

When I was a small child growing up in the mountains of West Virginia in the United States, on snowy days my family would gather around the kitchen table and play board games. One of my favorites was the board game Risk. It was a turn-based board game introduced in the 1950s.

Today, children would roll their eyes at the thought of playing a turn-based board game. The world has moved on. With gaming applications on their phones and multiple gaming devices, their fingers are constantly typing. It is a digital world with changing rules. The game is no longer limited by “turns.” The rules have changed, and the risk increased. For the supply chain leader it is not a game. The stake is business continuity.

Gamers do well in the world of supply chain. Designing value networks and managing “what-if” conditions is fundamental to managing supply chain risks.

The world is less certain than a decade ago. The move from regional to global supply chains increased risks. Geopolitical shifts, economic uncertainty, and demand/supply volatility are rising. In addition, to spur growth, companies are quick to add products to the item master, but slow to rationalize the portfolio. The rising complexity of items sold decreases the organization’s ability to forecast, and the longer lead times across multiple tiers of sourcing and supply increases the Bullwhip Effect’s impact (distortion of the demand signal across multiple tiers of the value network). This increases risk.

The world is less certain than a decade ago. The move from regional to global supply chains increased risks. Geopolitical shifts, economic uncertainty, and demand/supply volatility are rising. In addition, to spur growth, companies are quick to add products to the item master, but slow to rationalize the portfolio. The rising complexity of items sold decreases the organization’s ability to forecast, and the longer lead times across multiple tiers of sourcing and supply increases the Bullwhip Effect’s impact (distortion of the demand signal across multiple tiers of the value network). This increases risk.

Figure 1. Bullwhip Effect

Historically, the risk management focus was to reduce insurance costs. Today it needs to be much, much more. The focus needs to be on prevention, early sensing, and the execution of well-orchestrated plans to mitigate the impact of a disruption. Global supply chain leaders understand that designing and implementing robust risk management practices are essential and fundamental to running the business.

In my lifetime, supply chains have changed. They morphed from regional to global multinational organizations. Globalization and regulatory compliance increased. Procurement focus shifted from traditional programs focused on solely on contract management, price and term negotiations, and supplier scorecards, to include the evolution of supplier development to manage product quality and multi-tier supplier relationships in and across value chain relationships.

Technology has not caught up. The value network of suppliers and logistics providers is largely managed by spreadsheets and email with no system of record for interactions.

What Is Risk Management?

To ensure clarity, let’s start with a definition. We recently finished a study of 127 respondents and wrote a report. In the survey, supply chain risk management is defined as the proactive identification and assessment of potential risks to the supply chain along with the development of strategies to avoid these risks and avoid supply chain disruption.

A disruption is a failure in cost, quality or customer service. The event can be external or internal to the enterprise. It also can be material affecting performance to the degree that it must be declared, or stated, on the financial balance sheet in corporate reporting.

What Were the Most Significant Risks of the Last Five Years?

While the focus of the press is on major natural disruptions (hurricanes, floods, fires, etc.), in the past five years, the greatest disruptions for the supply chain leader were port issues.

Figure 2. Impact of Supply Chain Disruptions in the Past Five Years

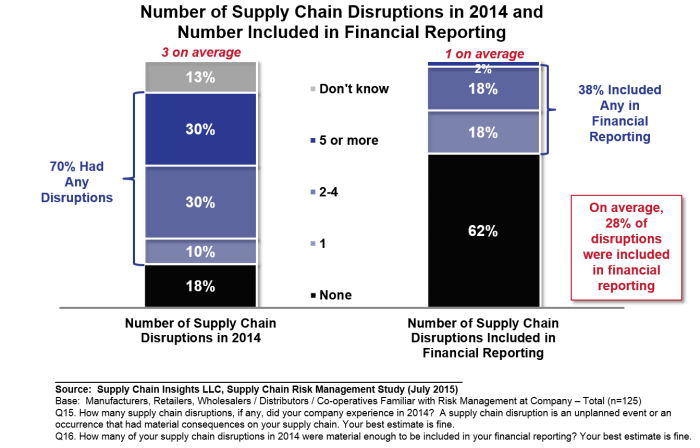

The impacts can be severe, resulting in material events. In 2014, 70% of companies experienced three business discontinuity events with at least one resulting in a material impact resulting in financial reporting on the balance sheet . This is significant. In the survey, 28% of the supply chain disruptions led to reporting balance sheet impacts.

Figure 3. Impact of Supply Chain Disruptions

The most advanced risk management programs are deeply rooted in preventive measures. Companies are aggressive in the design of inventory buffers, with active work through network design to build the right push-pull decoupling points, implementation of supplier monitoring and scorecarding, and the development of business continuity plans. The common threads are prevention and readiness.

In building and rethinking risk management programs, keep these five elements in mind:

- Leadership Matters. In this report, companies with leadership support rate themselves significantly more effective on the execution of risk management programs. This is not a program that is effectively managed bottoms-up.

- Focus on Multi-Tier Inventory Management. The management of the forms and function of inventory, and the design of the network, are paramount to buffer risk. Inventory is the most important buffer and companies with strong risk management programs define an inventory planning position and are active and knowledgeable about the use of multi-tier inventory management technologies.

- Implement Supplier Sensing and Supplier Visibility Programs. Visibility of suppliers–locations of facilities and their suppliers–is the first step. The second is supplier financial sensing. Companies with advanced risk management programs redesign the role of procurement to build, not just audit, value chain relationships.

- It Is About Much, Much More Than Technology. While technology vendors espouse risk management as a technology, it is much more than the deployment of a technology. While visibility technologies are an important part of the solution, they are not the answer.

- Things Happen. Not All Risks Can Be Prevented. Demand and supply risks are increasing. They cannot be totally prevented. The design of inventory buffers and supplier visibility programs are critical, but it is also important to have well-defined practices and drills to help the organization to mobilize quickly in the face of a disaster. It is not a time for indecision. When a disruption happens, there needs to be a clear definition of protocols and responsibilities. Many advanced companies implement drills and practice deployment to ensure readiness.

Conclusion

The global supply chain is a continual game of risk. Business continuity is at stake. The global supply chain has more risk than the regional supply chain of old. It requires an active and robust risk management program. The most successful risk management programs are multi-prong programs with an equal focus on prevention and recovery. The mature supply chain leader knows that a disruption lies ahead. It is impossible to eradicate risk; but, prevention and effective mobilization of resources reduces the business impact. Having a mature risk management program is the foundation for business continuity in the face of an uncertain world.

No comments:

Post a Comment