Getting the Right 3PL/4PL Strategy to Deliver Like Amazon

For many electronics companies, outsourcing certain aspects of the logistics process can lead to better business and improved customer support. By working with the right third party logistics (3PL or 4PL) companies, these manufacturers can stand out from the competition by offering new and better services.

3PL or 4PL companies provide a variety of services: warehousing, distribution, transportation, and sometimes even value added services, assembly services, packing services and more. Their core customer is one who would rather focus only on their product and core competency and do not want to worry about other aspects of running a successful business.

Of course, there are some clear differences between 3PL and 4PL offerings. To put it succinctly, 4PL companies own the end-to-end supply chain. These companies offer extra value added services that not every 3PL vendor offers. 4PLs also pro-actively offer additional help with monitoring the entire supply chain, looking for opportunities to optimize the supply chain and provide additional value added services that 3PLs won't offer.

Often both 3PL/4PL vendors are operating on thin margins due to competitive pressures, the nature of the products they carry, and the nature of the industry they serve. For example, the most challenging business is to be a 3PL that carries food products because not only the margins are insanely thin but any delay in addressing any exception or even a small mistake in timing (due to lack of visibility in the supply chain) could potentially result in the food product getting past the expiry date and not be sellable to the end customer.

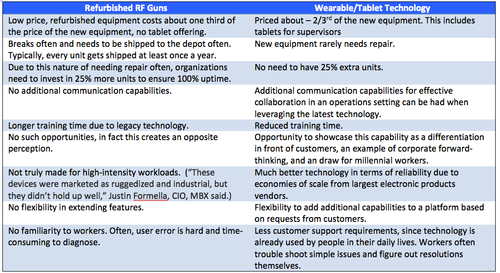

This competitive landscape can create holes in the services that logistics partners may offer. For example, to stay competitive, 3PL/4PL companies tend to buy every infrastructure possible at the lowest cost possible. Often, they end up buying refurbished scan guns and other refurbished hardware to save cost. This practice of price based procurement practice that they are blind to the potential cost of the practice. Let's take a look, for example, how refurbished RF guns compare to the newest wearable/tablet technology currently available in the market:

Clearly, wearable and tablet devices offer some clear benefits in terms of both cost effectiveness and capabilities to 3PL/4PL providers. Now, let's look at some of the ways that these technologies can create a clear differentiation from the competition and offer exponential gains to the business. By deploying a technology that gives wearable devices to operators, tablets for supervisors, and bring your own device (BYOD) apps for personnel that carry their own devices, 3PL or a 4PL vendor claim a number of benefits:

Differentiation – Demonstrate Uniqueness to Customers

Choosing forward-looking technologies allow organizations to be creative in trying to solve a customer issue or meet customer demand. As a new software engineer, at an all-hands meeting, the director of the well-known supply chain software vendor where I work shared a story about a customer demonstration he had witnessed. The customer's CIO wanted to know how the system could deal with exception handling from a technology perspective to support efforts to monitor the system health, get insight into under the hood problems and to look for cues of performance degradation or other issues. As everyone else was silent, the director immediately described the job error maintenance capability available in the package. This quick thought and knowledge of how to leverage the system's capabilities impressed the CIO and eventually won the deal. The company then made technical competence a key part of its sales process—and the director in question eventually became CEO of a billion dollar company in a different industry.

In the same way, 3PL/4PL vendors can showcase the latest wearable- and tablet-based technology to its vendors and demonstrate the ability to reach anybody, anytime in any of their distribution center. Consider the benefit of being able to reach out to the operator packing a shipment to get a status update in real-time or expedite the shipment for the customer's customer.

Enhance the customer experience

Typically, when 3PL/4PL companies integrate with their customer's business and systems, they follow one of two methodologies: loosely coupled and tightly coupled. In the loosely coupled model, there is no system-to-system integration. However, the customer's systems are made available within the four walls of the 3PL/4PL distribution centers and the 3PL/4PL operators log on to the customer's systems and perform the functions. The work gets done and the customer has full visibility of what is happening in their supply chain. In the tightly coupled model, systems are integrated and everything is done in the 3PL/4PL systems. Integration gives both the 3PL/4PL and the customer visibility into everything within both supply chains.

Imagine ability for customers to incorporate the special instructions in the form of videos detailing exact packing instructions. This not only showcases the ability for 3PL/4PL to accept video based instructions but also highlights the higher service level that an be offered.

But that's not all...

And finally wearable/tablet technology provides a number of additional benefits:

These days every 3PL/4PL vendor needs to anticipate this question. Anyone that sells a product that needs 3PL/4PL services needs to provide the same level of service that Amazon offers, and Amazon has been consistently raising the bar on service for its customers. Think about Prime Free Same Day Delivery, Amazon Dash, Prime Sale in the middle of July, and more.

It's very important for 3PL/4PL service providers to leverage every innovative technology that is available to meet this increasingly high bar. It is very difficult to match Amazon's service level because of the economy of scale advantages that Amazon has. However, it's better to be able to demonstrate that you are working to do everything you reasonably can.

3PL or 4PL companies provide a variety of services: warehousing, distribution, transportation, and sometimes even value added services, assembly services, packing services and more. Their core customer is one who would rather focus only on their product and core competency and do not want to worry about other aspects of running a successful business.

Of course, there are some clear differences between 3PL and 4PL offerings. To put it succinctly, 4PL companies own the end-to-end supply chain. These companies offer extra value added services that not every 3PL vendor offers. 4PLs also pro-actively offer additional help with monitoring the entire supply chain, looking for opportunities to optimize the supply chain and provide additional value added services that 3PLs won't offer.

Often both 3PL/4PL vendors are operating on thin margins due to competitive pressures, the nature of the products they carry, and the nature of the industry they serve. For example, the most challenging business is to be a 3PL that carries food products because not only the margins are insanely thin but any delay in addressing any exception or even a small mistake in timing (due to lack of visibility in the supply chain) could potentially result in the food product getting past the expiry date and not be sellable to the end customer.

This competitive landscape can create holes in the services that logistics partners may offer. For example, to stay competitive, 3PL/4PL companies tend to buy every infrastructure possible at the lowest cost possible. Often, they end up buying refurbished scan guns and other refurbished hardware to save cost. This practice of price based procurement practice that they are blind to the potential cost of the practice. Let's take a look, for example, how refurbished RF guns compare to the newest wearable/tablet technology currently available in the market:

Clearly, wearable and tablet devices offer some clear benefits in terms of both cost effectiveness and capabilities to 3PL/4PL providers. Now, let's look at some of the ways that these technologies can create a clear differentiation from the competition and offer exponential gains to the business. By deploying a technology that gives wearable devices to operators, tablets for supervisors, and bring your own device (BYOD) apps for personnel that carry their own devices, 3PL or a 4PL vendor claim a number of benefits:

Differentiation – Demonstrate Uniqueness to Customers

Choosing forward-looking technologies allow organizations to be creative in trying to solve a customer issue or meet customer demand. As a new software engineer, at an all-hands meeting, the director of the well-known supply chain software vendor where I work shared a story about a customer demonstration he had witnessed. The customer's CIO wanted to know how the system could deal with exception handling from a technology perspective to support efforts to monitor the system health, get insight into under the hood problems and to look for cues of performance degradation or other issues. As everyone else was silent, the director immediately described the job error maintenance capability available in the package. This quick thought and knowledge of how to leverage the system's capabilities impressed the CIO and eventually won the deal. The company then made technical competence a key part of its sales process—and the director in question eventually became CEO of a billion dollar company in a different industry.

In the same way, 3PL/4PL vendors can showcase the latest wearable- and tablet-based technology to its vendors and demonstrate the ability to reach anybody, anytime in any of their distribution center. Consider the benefit of being able to reach out to the operator packing a shipment to get a status update in real-time or expedite the shipment for the customer's customer.

Enhance the customer experience

Typically, when 3PL/4PL companies integrate with their customer's business and systems, they follow one of two methodologies: loosely coupled and tightly coupled. In the loosely coupled model, there is no system-to-system integration. However, the customer's systems are made available within the four walls of the 3PL/4PL distribution centers and the 3PL/4PL operators log on to the customer's systems and perform the functions. The work gets done and the customer has full visibility of what is happening in their supply chain. In the tightly coupled model, systems are integrated and everything is done in the 3PL/4PL systems. Integration gives both the 3PL/4PL and the customer visibility into everything within both supply chains.

Imagine ability for customers to incorporate the special instructions in the form of videos detailing exact packing instructions. This not only showcases the ability for 3PL/4PL to accept video based instructions but also highlights the higher service level that an be offered.

But that's not all...

And finally wearable/tablet technology provides a number of additional benefits:

- Productivity gains.

- The ability to bring new operators to full-efficiency quickly.

- The flexibility to add new capabilities to a platform

- A lower total cost of ownership or better abilities at the same cost.

These days every 3PL/4PL vendor needs to anticipate this question. Anyone that sells a product that needs 3PL/4PL services needs to provide the same level of service that Amazon offers, and Amazon has been consistently raising the bar on service for its customers. Think about Prime Free Same Day Delivery, Amazon Dash, Prime Sale in the middle of July, and more.

It's very important for 3PL/4PL service providers to leverage every innovative technology that is available to meet this increasingly high bar. It is very difficult to match Amazon's service level because of the economy of scale advantages that Amazon has. However, it's better to be able to demonstrate that you are working to do everything you reasonably can.

No comments:

Post a Comment