Direct Store Delivery: Mondelēz International’s Mobile Journey

One of the key aspects of omni-channel retailing is merchandise availability. This pertains to the store, warehouse, and distribution center. With so much effort and focus being spent on building out omni-channel strategies starting at the store, merchandise availability within the store is of critical importance. Another company that presented at the CSCMP Annual Global Conference in San Antonio, TX was Mondelēz International. Headquartered in Deerfield, IL, Mondelēz International comprises the global snack and food brands of the former Kraft Foods. The company manages well known snack brands around the globe in different categories, including cookies and crackers (Oreo; Chips Ahoy!; and Triscuit), chocolate (Côte d’Or, Toblerone, and Cadbury Dairy Milk), and gum and candy (Trident, Chiclets, and Halls). The company’s presentation focused on a growing concern for many brands: Direct Store Delivery (DSD).

One of the key aspects of omni-channel retailing is merchandise availability. This pertains to the store, warehouse, and distribution center. With so much effort and focus being spent on building out omni-channel strategies starting at the store, merchandise availability within the store is of critical importance. Another company that presented at the CSCMP Annual Global Conference in San Antonio, TX was Mondelēz International. Headquartered in Deerfield, IL, Mondelēz International comprises the global snack and food brands of the former Kraft Foods. The company manages well known snack brands around the globe in different categories, including cookies and crackers (Oreo; Chips Ahoy!; and Triscuit), chocolate (Côte d’Or, Toblerone, and Cadbury Dairy Milk), and gum and candy (Trident, Chiclets, and Halls). The company’s presentation focused on a growing concern for many brands: Direct Store Delivery (DSD).

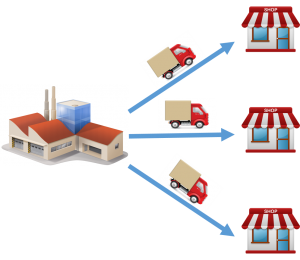

One of the major issues for a retailer is whether they have the merchandise in the store. Often, a retailer receives a truck with items and merchandise from multiple manufacturers and distributors. However, other brands choose to utilize the DSD model. The DSD model is mostly seen in the food and beverage industry, especially at smaller convenience and grocery stores. Direct Store Delivery gives the manufacturer more control over replenishment and merchandising within the store. However, one of the major problems is the case of late deliveries. If a retailer is waiting for a specific delivery to finalize merchandise assortments, and it is late, it can throw off the entire day’s plan.

Mondelēz International came up with a solution to this problem, and sees the solution as the future of their DSD operations: mobile logistics. The mobile logistics platform is used to manage alerts and deliveries, comply with safety and DOT requirements, track assets through GPS, and provide basic communication functions. The introduction of “late alerts” was groundbreaking for the company and its retail partners, as it allowed the merchandiser to re-prioritize their day. Rather than waiting and wondering what time the delivery would arrive, they had an updated delivery time-frame which allowed them to focus on other tasks.

Mondelēz International came up with a solution to this problem, and sees the solution as the future of their DSD operations: mobile logistics. The mobile logistics platform is used to manage alerts and deliveries, comply with safety and DOT requirements, track assets through GPS, and provide basic communication functions. The introduction of “late alerts” was groundbreaking for the company and its retail partners, as it allowed the merchandiser to re-prioritize their day. Rather than waiting and wondering what time the delivery would arrive, they had an updated delivery time-frame which allowed them to focus on other tasks.

According to Mondelēz International, the biggest challenge was linking the three main components to DSD: the driver, the retailer, and the customer care center. The company was able to synchronize sales and distribution communication to establish a single roadmap for all three parties. By connecting the driver with the retailer, it eliminated the need to rely on customer care to deliver the message. In the past, the driver would contact customer care to let them know they were running late. In turn, customer care would contact the retailer. This delayed the process and did not always guarantee the right information was shared. The new connection allows the driver to communicate directly with the retailer with real-time updates. The result was growth in sales and a higher percentage of on-time deliveries.

Looking forward. Mondelēz International plans to continue to build out their mobile capabilities. From driver tracking to insight into multi-day rates, enhancements are expected to be added through-out the remainder of 2014 and beyond. The overall capabilities will eventually be leveraged globally for all area that use DSD as part of their distribution model.

This blog share nice strategy of logistic to made every delivery successful and importance of fast mile logistics, final mile.

ReplyDelete