The Biggest Challenges Supply Chain Leaders Will Crush in 2016

To be fair, it’s nearly impossible to predict what will turn out to be the biggest challenges supply chain leaders will encounter in the year ahead. By Henry Canitz

…

February 15, 2016

Millions of supply chains face unique challenges that vary across industries, geographies and business strategies.

A host of unpredictable factors will certainly arise, such as geopolitical conflict, social and economic upheaval, natural disasters, and more.

But despite the difficulty factor, let’s gaze into a crystal ball and make a few predictions about the challenges supply chain leaders should be preparing to face in 2016.

1. Increased Disruptions

It is not a matter of if disruptions will take place, but rather when and where. Today’s supply chains are characterized by complexity, volatility, unpredictability, and instability. Their many links span a wide geography, which increases the probability of disruption.

It is not a matter of if disruptions will take place, but rather when and where. Today’s supply chains are characterized by complexity, volatility, unpredictability, and instability. Their many links span a wide geography, which increases the probability of disruption.

Earthquakes, hurricanes, tidal waves, and wars lead to massive consequences that require extensive mitigation efforts, but even smaller factors like adverse weather, accidents, and power outages can create a bullwhip effect that ultimately impacts a company’s ability to service customers.

The discipline of supply chain risk management has emerged over the last decade to promote creation of mitigation plans for when disruptions occur. In 2016, more supply chain teams will invoke scenario planning to determine what actions to take in the face of potential disruptions. Greater supply chain visibility also enables faster response to supply chain disruptions, and supply chain systems will be called upon to increase both inbound and outbound product visibility.

Advice from the pros:

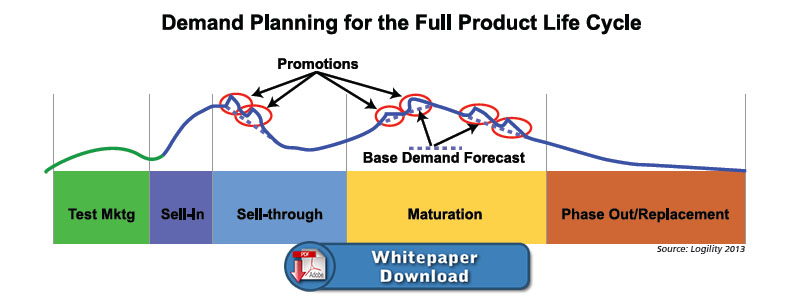

Give Portfolio Review prominence in the S&OP process, as often the success of S&OP hinges its effectiveness. Employ advanced techniques such as attribute-based planning, which allows a company to accurately forecast new products even when no direct prior sales history exists.

Give Portfolio Review prominence in the S&OP process, as often the success of S&OP hinges its effectiveness. Employ advanced techniques such as attribute-based planning, which allows a company to accurately forecast new products even when no direct prior sales history exists.

Technology enablers: Logility’s supply chain optimization solutions provide customizable views to review plans for new product introductions (validate sales projections, expected launch dates, consumption forecasts, pipeline fill), and for products that are phasing out (manage the depletion of inventory, transition to new products). Leverage Logility’s cluster and Lifecycle Planning functionality to develop forecast profiles based on aggregate new product launch history.

2. Supply Chain Cost Reductions

Fuel price drops reduced overall transportation costs in 2015, but it’s unclear whether lower fuel costs will continue. Certainly interest rates will rise, which will drive up the cost to hold inventory. The cost to hire and retain qualified talent will rise - perhaps sharply, if current trends continue. Raw material prices are on an upward trend as well. But regardless of what is happening to resource and labor prices, senior management will expect the supply chain team to continue lowering total cost.

In 2016, there will be increased adoption of supply chain planning, optimization, and execution technology to automate supply chain processes and manage by exception. This will result in more time for value-added activities like scenario analysis, process reengineering and developing value added differentiating services.

3. Customer Service Expectations

Customers have more information available to them than ever before and they use this information to demand larger product variety at a lower price whether shopping on-line or in a store. In 2016, supply chains that support on-line, catalog, brick & mortar, and wholesale channels will need to be fully synchronized to meet customer requirements efficiently. With Amazon and other on-line retailers setting high availability and delivery expectations, supply chain managers will have to take stock in 2016, and understand their customers’ expectations.

Customers have more information available to them than ever before and they use this information to demand larger product variety at a lower price whether shopping on-line or in a store. In 2016, supply chains that support on-line, catalog, brick & mortar, and wholesale channels will need to be fully synchronized to meet customer requirements efficiently. With Amazon and other on-line retailers setting high availability and delivery expectations, supply chain managers will have to take stock in 2016, and understand their customers’ expectations.

Companies will need integrated supply chains to meet the requirements of each unique sales channel, with an integrated management team supported by a shared end-to-end supply chain planning and execution solution.

4. Demand Unpredictability

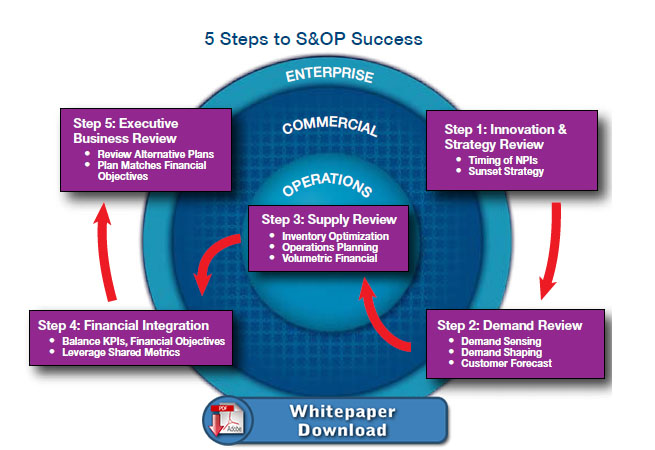

Supply chain growth over the last few years has gone hand-in-hand with growing demand uncertainty. In 2016, more supply chain teams will need to upgrade their planning and optimization capabilities to plan for both short and longer term demand variability.

Supply chain growth over the last few years has gone hand-in-hand with growing demand uncertainty. In 2016, more supply chain teams will need to upgrade their planning and optimization capabilities to plan for both short and longer term demand variability.

The disciplines of demand planning and sales and operations planning (S&OP) have been around for many years, but recent advances in supply chain management technology have enabled integrated planning and optimization over short, mid, and long term horizons. In 2016, companies will accelerate their adoption of supply chain software solutions that are easy to use, powerful, and provide collaborative and mobile capabilities.

Step 1 - Innovation and Strategy Review

An important consideration for any company is managing product lifecycles.

- What products should we introduce to the market place?

- When should we introduce them?

- What products should we sunset or discontinue?

These are all critical questions to answer and the impact on sales, production, inventory, and finance must be understood.

Introducing new products is a key aspect of the innovation and strategy review. NPIs can significantly impact the well being of a company including inventory and lost sales. The ability to predict sales on NPIs, where there is no sales history to model, can be difficult. Traditional time-series forecasting tools that utilize history will not work effectively for NPIs. To overcome these challenges, more advanced techniques must be employed.

Companies that have been successful in managing NPIs utilize advanced techniques such as attribute-based forecasting which generates demand profiles for new products based on existing product demand tied to identifiable attributes such as style, color, season, material type, etc. A well-designed attribute-based forecasting system will continually monitor demand signals, quickly recognize any deviation from the forecast, and adjust the assumptions and forecast to match the actual demand signals.

So how do you meet all of these challenges?

- Don’t try to go it alone. Get input from peers and advisors. Get involved with professional organizations. Engage a third party. Take advantage of an abundance of on-line thought leadership.

- Take a systematic approach. List all the challenges you may face in the next several years. Prioritize this list and identify the top three to five actions to be tackled in the next 18 months. Brainstorm ideas on how each challenge could be met (people, process, technology). Determine a logical order for how challenges should be addressed. Develop a high-level project plan.

- Build ROI business justifications. Socialize improvement projects with key executives and stakeholders. Reevaluate priority and sequence based on feedback, alternative priorities, business impacts, etc. Develop a compelling business case for supply chain management improvement.

- Engage technology solution providers early. Supply chain management vendors are good sources of advice on best practices and process improvement. A good solution provider will partner with you and help build your business case for making the improvements.

- Get started. How do you eat an Elephant?

No comments:

Post a Comment