Reverse Logistics: Data in the Details

Companies need to start taking a closer look at reverse logistics. With a sufficient amount of data available to be analyzed and applied correctly, it could further improve their bottom line.

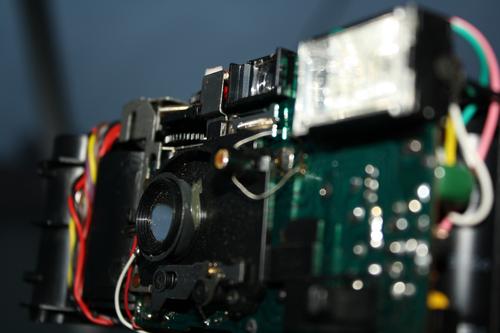

Reverse logistics has always carried a stigma in the world of supply chain management. Known as the process associated with maximizing the value of a product and its materials after it has been returned by the consumer, reverse logistics is often disregarded as nothing more than just a collection of defective, damaged and unwanted goods that end up in the darkest corners of a manufacturer's warehouse. Many businesses end up storing these damaged goods, not realizing that these returned products, their materials and the information contained within them, could prove a lucrative reinvestment – and may even end up improving a retailer's bottom line through either refurbishment or recycling. The days of ignoring your company's reverse logistics and the potential revenue generation they may create are gone. Follow these steps to ensure you are taking advantage of everything your reverse logistics process may have to offer: More than just damaged goods The first step toward turning a standard reverse logistics process into a true value driver for a business is making a commitment to seeing reverse logistics as much more than a simple returns process for defective products. By recognizing screen-cracked mobile devices and overstocked outdated televisions as reusable internal parts for refurbished or new products – and not just old technology that can no longer be sold on store shelves – companies can begin taking charge of their reverse logistics processes and recognizing the hidden value within them. These products may also fall into the "No Fault Found" category or simply need a small part replaced, making it quick and easy to get the returned product back onto store shelves. By feeding these products back into production, reselling them, or even recycling them for materials to be reused, companies can gain value from these returned products – which wouldn't be possible if they were still sitting untouched in a warehouse. Review the other 75% While recalled and defective products prove an important part of the reverse logistics pipeline, they only account for about 25% of the total value of all assets processed in traditional reverse logistics operations. Everything from overstocks to asset liquidation or end-of-life goods falls under the reverse logistics umbrella. All of these products should be subject to the same review process as defective products as many of their parts can be reused or recycled as well. Analyze the hidden data Although there is value to be recognized when turning a damaged good into a refurbished one, the greatest hidden value may come from learning what caused the product to be damaged in the first place. Visibility into the reverse logistics process means that businesses should have the data necessary to determine exactly what landed that defective product into its respective warehouse. By tracking and accumulating this data, companies can determine common issues that deem their products defective. By using that information when developing the product's next iteration, the business has the knowledge of how to make it more durable and/or include more up to date technology, which can lead to an increase in sales for the business. Also, keeping track of the costs associated with replacement parts can prove to be very helpful when developing the follow-up products in the event that they too get carried over into the next version. Conclusion As supply chains continue to innovate and create new efficiencies surrounding even their most traditional processes, it is imperative that supply chain managers establish a strong reverse logistics process – one that will not only enable the company to pull some value out of returned products through recycling and refurbishment, but will also help the company better understand why those products were returned in the first place so they can use that knowledge to improve the way products are made and rolled out to consumers. Realizing the value of a reverse logistics process can be the difference maker when it comes to staying ahead of the competition. |

Wednesday, December 23, 2015

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment