Will Tesla Disrupt Long Haul Trucking?

Summary

Tesla says it will show us a world beating semi-truck this September - something the industry believes impossible.

Commercial long haul trucking is all about economics. Lower cost per mile matters, bling doesn't count. Can Tesla pull this off?

Tesla's semi truck will use Model 3 motors suggesting a radical departure in truck design. If successful this could let Tesla win.

Tesla's technology and experience with grid storage can enable a strongly competitive electric truck business model.

If Tesla's truck is a success, very rapid, economics-driven truck industry transition could further stress battery supply chains.

Commercial long haul trucking is all about economics. Lower cost per mile matters, bling doesn't count. Can Tesla pull this off?

Tesla's semi truck will use Model 3 motors suggesting a radical departure in truck design. If successful this could let Tesla win.

Tesla's technology and experience with grid storage can enable a strongly competitive electric truck business model.

If Tesla's truck is a success, very rapid, economics-driven truck industry transition could further stress battery supply chains.

Tesla (NASDAQ:TSLA) tells us that come September, it will unveil a powerful, long-range, all-electric semi truck. Tesla isn't talking about a short range, specialty truck for delivering feathery light croissantes from the bakery to some Silicon Valley Sunday brunch. This Tesla truck is supposed to haul heavy line-haul freight over long distances, across mountain ranges from one end of America to the other. Tesla's electric truck will supposedly compete with the best diesel rigs on the basis of cost in an industry that looks at cost down to fractions of a cent per mile.

Trucking is a highly competitive industry, driven almost entirely by cost, cost, and cost. Even the coffee truckers drink ($0.004/mile) is a consideration. Tesla has sold a lot of electric cars on the basis of high performance and 'bling', but can Tesla engineers sharpen their pencils, put on their green eyeshades, and compete on cost? If Tesla can build a world-beating semi-truck that also delivers lower overall per mile cost, it might disrupt another industry. And, that is something investors should care about.

There is just one thing. Everyone in the industry "knows" that a realistic battery - electric truck isn't possible. Batteries weigh too much. Batteries cost too much. Batteries take too long to recharge. While it might be possible to make a fuel cell - electric truck that could be refueled with hydrogen, or a diesel truck that uses liquefied natural gas, there is absolutely no way ever, ever that a battery truck can do this job.

There is just one thing. Everyone in the industry "knows" that a realistic battery - electric truck isn't possible. Batteries weigh too much. Batteries cost too much. Batteries take too long to recharge. While it might be possible to make a fuel cell - electric truck that could be refueled with hydrogen, or a diesel truck that uses liquefied natural gas, there is absolutely no way ever, ever that a battery truck can do this job.

Seeking Alpha author John Peterson recently explained that an electric semi-truck will necessarily weigh too much, and in any case, the pollution from diesel trucks has been a solved problem for a decade - so why bother. Anton Wahlman suggests Toyota (TM) has beat Tesla to the green truck market with its 200-mile-range fuel cell - electric demonstrator truck. Donn Bailey believesTesla is reaching too far in its quest to change long haul trucking. I have great respect for these authors, and each of them has made thoughtful and reasoned arguments.

Contacts in the industry tell me that several electric truck projects are up against the very problems these authors describe. Nonetheless, I believe Tesla can, and likely will, deliver a world beating, long range, all electric semi truck. Tesla's unique approach to electric propulsion using high speed induction motors and integrated thermal management for batteries, motors, and power electronics, combined with its high volume electric car production and experience in grid storage will enable it to achieve what others believe impossible.

In this article, we will look at three things. First, the technical aspects of long haul trucks will be explored, and a likely Tesla approach that enables longer range, higher performance, and reasonable weight will be shown. Second, operation of electric semi trucks will be explored, and from that, a business model and comparative costs will be developed. Finally, implications of Tesla's entry into the heavy truck market will be analyzed for existing market players, for Tesla's other businesses, and for the increasingly critical battery and battery materials supply chain.

Before we do that, there is something to say. The following presentation of a potential (likely?) Tesla semi truck and operating business model is undertaken to assess whether or not Tesla could surprise technologists and the market with their electric semi truck. The underlying supposition is that being smarter than I am and working harder than I do, Mr. Musk and his team can be expected to do as well, and probably a good deal better than what is presented here. And no, I have no illusion that Tesla engineers will tack this article to their cubicles.

Technology Issues

Heavy Class 8 semi trucks are a well established, commodity product delivered by a mature industry using diesel engine technology. These semi trucks are really more "tractor" than "truck" - in fact semi trucks are often referred to as "tractor-trailers" which is exactly what they are. The tractor is not much more than a huge diesel engine, transmission and drivetrain attached to a fifth-wheel (the thing the trailer hooks on to) and some wheels to let it roll along. The body is just there to keep rain and bird poop off the machinery, give the driver a place to sit and to push air out of the way as the contraption drives down the road.

What is important for our discussion of a likely Tesla electric semi truck (tractor) is that these trucks are crammed with lots of big, heavy machinery. Any solution that doesn't get rid of that machinery will not have the room or the weight carrying capacity for a large battery. And, without a large battery, an all electric truck isn't going very far, down the road or in the marketplace.

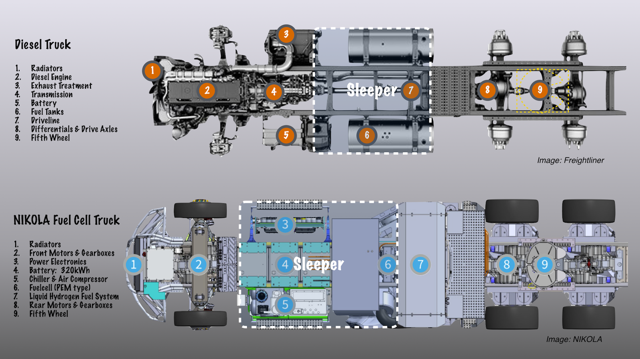

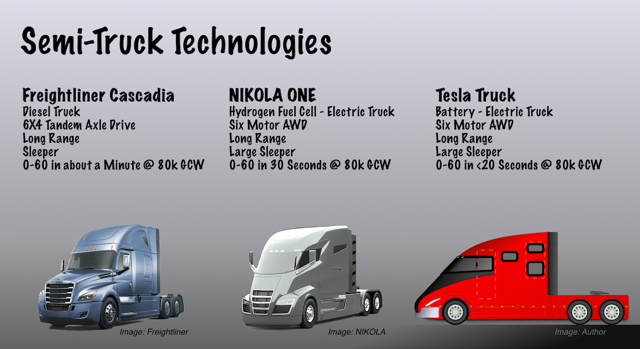

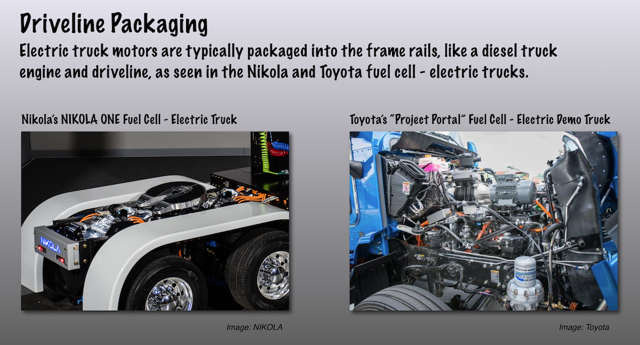

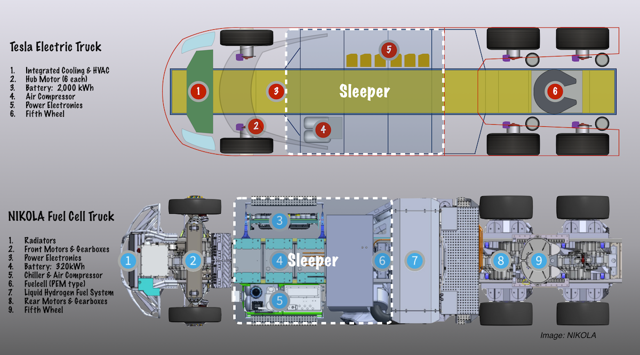

The following illustrations of Daimler's (OTCPK:DDAIF) Freightliner and Nikola Motors NIKOLA ONE chassis illustrate this situation.

Mechanical Arrangement of Diesel and Fuel Cell - Electric Trucks

With both the diesel truck and the fuel cell - electric truck, much of the central frame area gets filled up with heavy machinery - diesel engine, transmission, driveline, differentials, and axles in the case of the diesel and electric motors, gearboxes half-shafts and independent suspension in the fuel cell - electric truck.

With both the diesel truck and the fuel cell - electric truck, much of the central frame area gets filled up with heavy machinery - diesel engine, transmission, driveline, differentials, and axles in the case of the diesel and electric motors, gearboxes half-shafts and independent suspension in the fuel cell - electric truck.

The NIKOLA ONE does have room for a 320 kWh battery, good for 100+ miles of electric range, but the truck had to be lengthened to accommodate a fuel cell "range extender" to get useful range. It is not practical to pile batteries higher to fit more within the available frame length because that would make the truck too heavy. These pictures give an idea how much machinery gets loaded into the central frame for a conventional electric or fuel cell - electric truck.

Tesla Technical Advantage

Here is where Tesla's technology advantages and electric car manufacturing and design experience become important. Tesla does three things differently in its electric cars that translate directly to the solution for getting a big battery into a truck without making the truck too big or too heavy.

- Tesla uses induction motors rather than permanent magnet motors. Induction motors can operate efficiently at higher speed and over wider range of speeds, reducing weight while increasing power.

- Tesla uses integrated thermal management and liquid cooling for its battery, power electronics, motors, and passenger compartment. Liquid cooling and active cooling (i.e. use of refrigeration to reduce coolant temperature below ambient.) allow motors to operate continuously at higher power levels than allowed by other cooling approaches - something that is important for trucks that must pull heavy loads up long mountain grades.

- Tesla will be using a new induction motor for its high volume Model 3 electric car. Several of these motors used together will match nicely the power and torque requirements for a long range, line-haul truck. And, Elon Musk has said that is exactly what Tesla will do.

The engineering bottom line from combining high speed induction motors, active liquid cooling, and a volume production motor design is that Tesla will be able to move both motors and gearboxes into the wheel hubs and out of the central frame. This will save weight and open up space for a very large battery and give Tesla's electric truck very long range.

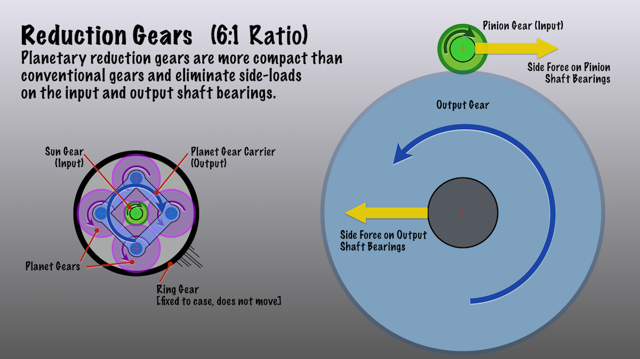

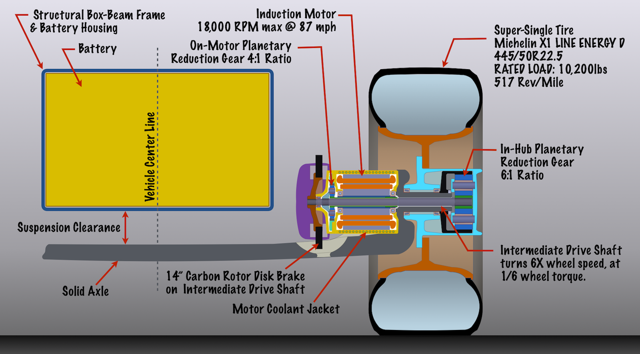

To begin this technical discussion, we need to appreciate the differences between "conventional reduction gears" like Tesla uses in Model S and Model X and "planetary reduction gears" which are regularly used in automatic transmissions and turboprop aircraft engines. I know this is a bit geeky, but bear with me.

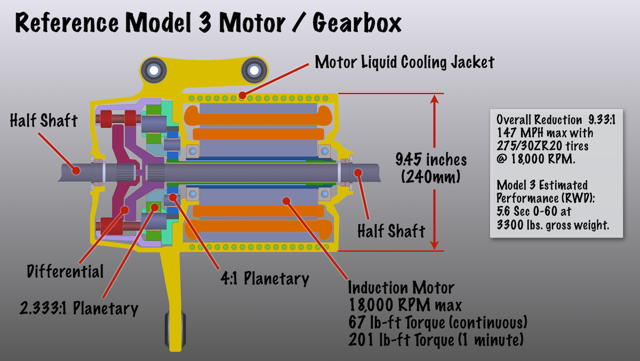

Tesla is likely to shift to a planetary reduction gearbox for Model 3. The side load on the high speed motor shaft bearings in the Model S and Model X is likely the significant bearing life limiting factor, and a planetary reduction gear eliminates this side load. A planetary reduction gear will also be a lot smaller and lighter - and cheaper. The drawback is that a planetary gearbox requires integrating design of motor and gears together, making it a more difficult design and development problem. A Model 3 motor and planetary reduction gear might look something like this.

Tesla is likely to shift to a planetary reduction gearbox for Model 3. The side load on the high speed motor shaft bearings in the Model S and Model X is likely the significant bearing life limiting factor, and a planetary reduction gear eliminates this side load. A planetary reduction gear will also be a lot smaller and lighter - and cheaper. The drawback is that a planetary gearbox requires integrating design of motor and gears together, making it a more difficult design and development problem. A Model 3 motor and planetary reduction gear might look something like this. In this sketch, the electric motor has been scaled based on a similar but smaller Astronics (ATRO) aircraft induction starter-generator. The outside diameter of the motor is less than 10 inches, the diameter of a heavy truck hub reduction drive axle.

In this sketch, the electric motor has been scaled based on a similar but smaller Astronics (ATRO) aircraft induction starter-generator. The outside diameter of the motor is less than 10 inches, the diameter of a heavy truck hub reduction drive axle.

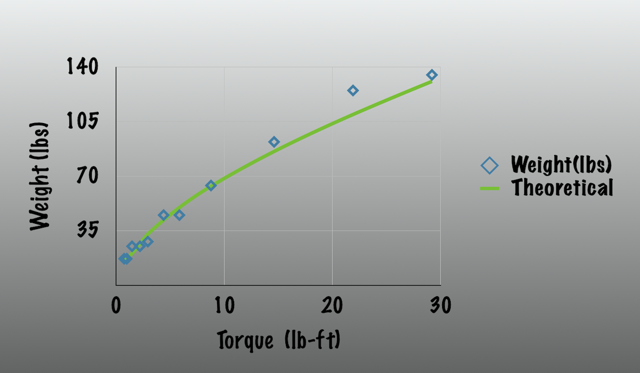

The scaling relationship is that the volume and weight of an induction motor vary as the 3/5ths power of the rated motor torque. For example, this figure compares weight and torque of a series of similar design induction motors to this theoretical 3/5ths power scaling relationship.

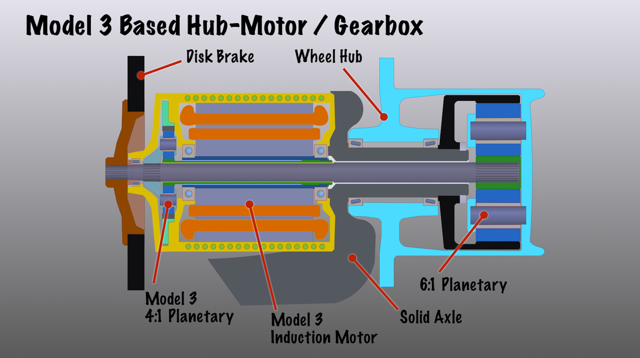

Combining the motor and first planetary reduction gear from the Model 3 with a 6:1 planetary hub reduction gear similar to the Arvin-Meritor axle linked above results in a "hub motor" something like this.

In this design, a carbon rotor disk brake is fitted to the intermediate drive shaft, replacing the heavy duty disk or drum brake normally used. This is a practical size and weight-saving approach for a Tesla all electric truck because the motors and battery system are sized for high torque/power and can absorb (regenerate) energy on long, steep downgrades at high speed, leaving the brakes used only for final stopping or emergency situations. So, while the small, high speed disk brake will have much higher wear and shorter pad life than a large "truck size" brake, this is not a problem because these brakes are only rarely used.

In this design, a carbon rotor disk brake is fitted to the intermediate drive shaft, replacing the heavy duty disk or drum brake normally used. This is a practical size and weight-saving approach for a Tesla all electric truck because the motors and battery system are sized for high torque/power and can absorb (regenerate) energy on long, steep downgrades at high speed, leaving the brakes used only for final stopping or emergency situations. So, while the small, high speed disk brake will have much higher wear and shorter pad life than a large "truck size" brake, this is not a problem because these brakes are only rarely used.

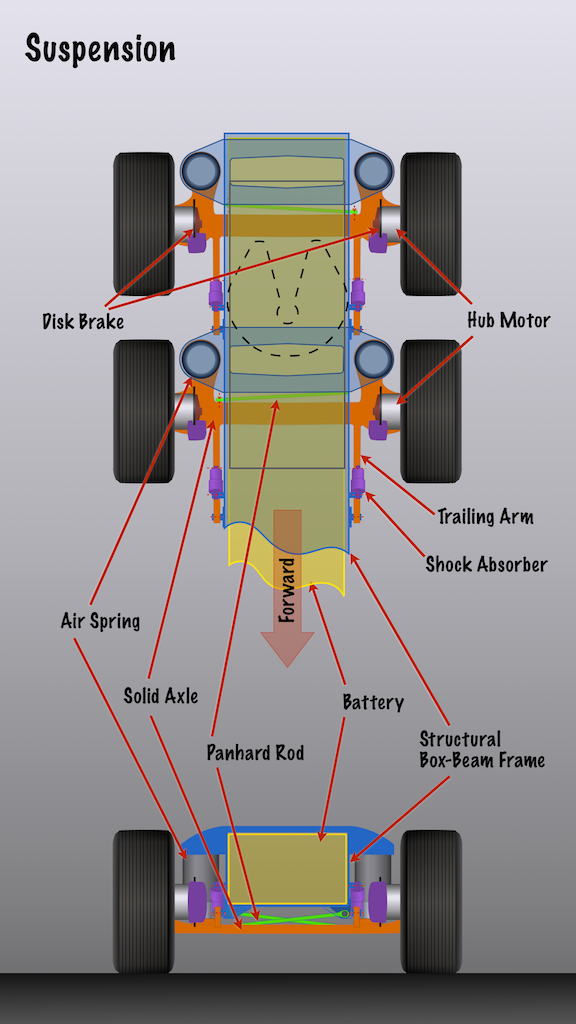

Where all this effort to apply Model 3 motors to an in-wheel or "hub motor" design pays off is shown in this sketch.

By combining likely Model 3 motor and gearbox elements with conventional heavy truck hub reduction gears, a small, compact electric driveline results. At the same time, the central spine of the truck is made available to house a very large battery.

By combining likely Model 3 motor and gearbox elements with conventional heavy truck hub reduction gears, a small, compact electric driveline results. At the same time, the central spine of the truck is made available to house a very large battery.

The drive approach shown, using a solid axle allows for a particularly simple and robust trailing arm and air-spring suspension similar to that used on many of today's diesel trucks.

Simplicity and robustness of a truck suspension is important because suspensions experience extreme forces when hauling heavy loads and because maintenance requirements for a complex suspension and driveline can drive up per-mile operating cost.

Simplicity and robustness of a truck suspension is important because suspensions experience extreme forces when hauling heavy loads and because maintenance requirements for a complex suspension and driveline can drive up per-mile operating cost.

Interestingly, each solid axle - hub motors - disk brake combination shown here weighs somewhat less than a corresponding diesel truck differential, axle, and brake equivalent.

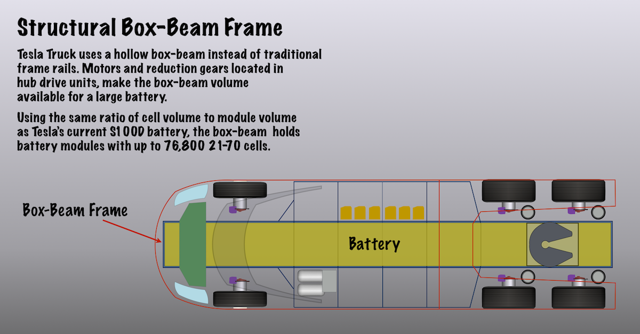

The importance of placing the drive motors and their reduction gears in the wheel hubs is that the center frame of the truck becomes available to hold a really large battery. As illustrated, the frame rails of a conventional truck are replaced by a simple, large cross-section, hollow rectangular beam running the length of the truck. Modules containing Tesla's new 21-70 cells fill the interior of this structural beam.

Each battery module used in the current Model S and Model X 100kWh batteries has a volume envelope (exterior prismatic envelope including mounting lugs) of about 15.4 liters and contains 516 18650 form factor cells, the volume of the cells occupying about 55% to the envelope volume. Using this same 55% volume packaging factor, the box-beam frame as shown holds 76,800 21-70 cells. Taking the density of these 21-70 cells to be the same as Tesla's 18650 cells, each 21-70 cell weighs 67.4 grams and the 76,800 cells together weigh 11,393 pounds (5,178kg). Allowing an additional 25% weight for the module containers, wiring, coolant tubes, etc., total weight of the battery modules, not including the weight of the structural box-beam itself is 14,241 pounds (6,473kg). Yes, the battery is heavy, but as we shall see in a bit, this isn't the last word on battery weight.

The simplicity and packaging efficiency of the Tesla truck is a key element that will make Tesla successful. Comparing the layout of the Tesla truck to that of the NIKOLA ONE shows how much simpler is this approach compared to a traditionally packaged truck with driveline components mounted to the frame.

The simplicity and packaging efficiency of the Tesla truck is a key element that will make Tesla successful. Comparing the layout of the Tesla truck to that of the NIKOLA ONE shows how much simpler is this approach compared to a traditionally packaged truck with driveline components mounted to the frame.

To understand how well or poorly will the Tesla electric truck compete against current diesel and potential future fuel cell - electric trucks, we must know what its performance is. In calculating the Tesla truck performance, various parameters were used, and these are summarized below.

| Parameter | Value | Description |

| Cell Specific Energy | 371 Wh/kg | Energy stored in each kg of cells. Assumes a 40% improvement over 2012 Model S cell architecture and chemistry in 2019. (<5%/yr improvement) |

| Inverter+Motor Efficiency | 85% | Efficiency converting battery energy to mechanical energy at motor output shaft. |

| Gearbox Ratio | 24:1 | 4:1 x 6:1 planetary reduction gear |

| Gearbox Efficiency | 97% | Power loss in gearbox is 3% of input mechanical power. |

| Revolutions / mile | 517 | Tire revolutions per mile |

| Effective Radius | 18.5 inches | For converting wheel torque to thrust Source: Michelin Tire Data Book |

| Rolling Coefficient | 0.0055 | Rolling resistance as fraction gross weight. |

| Drag Coefficient | 0.32 | Aerodynamic Drag Coefficient SuperTruck baseline, 42% stated improvement with minor additional reduction for lower cooling airflow. |

| Frontal Area | 113.4 sq.ft. | Area of frontal cross-section Source: SuperTruck White Paper |

| Motor Continuous Power (each motor) | 185HP (138kW) | 67 lb-ft @ 14,500 RPM [70MPH, 6% grade, 80k GCW], 5C Chilled Coolant Inlet Temp. |

| Motor Peak Torque (each motor, for 1 minute) | 201 lb-ft | Magnetic Saturation & Thermal Limit |

| Inverter Peak Power (each inverter) | 350kW | Max power from battery (per Motor) |

| Peak Motor Power (each motor) | 398HP (297kW) | Motor Power Limit from max battery power limit (per motor) |

| Maximum Motor Speed | 18,000 RPM |

From these parameters, the following truck performance characteristics were derived. In all cases, these characteristics are for a combination of the Truck and a Trailer with GCW (Gross Combination Weight) of either 60,000 pounds or 80,000 pounds, as indicated and operating under no wind, sea level conditions.

| Characteristic | Value | Notes |

| Top Speed | 87 MPH | 80k GCW (limited by max motor RPM) |

| Continuous Speed, 6% Grade | 70 MPH | 80k GCW (Limited by motor cooling) |

| Acceleration 0-60 MPH | <20 seconds | 80k GCW, 0% grade |

| Battery Capacity | 2MWh | Rated Capacity (1,921 kWh useable) See description smaller battery options below. |

| Range at 65 MPH | 1,086 miles | 60k GCW |

| Range at 75 MPH | 928 miles | 60k GCW |

| Range at 75 MPH | 832 miles | 80k GCW |

| Curb Weight (2MWh battery) | 24,133 pounds | |

| Curb Weight (1MWh battery) | 17,012 pounds |

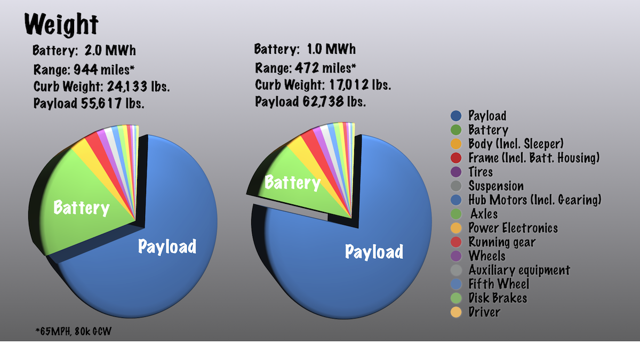

Before considering weights and payloads, I need to point out that the battery in the truck need not be a full 2MWh. There are many applications where a smaller battery that reduces the weight of the truck, allowing greater payload in exchange for shorter range is a more economic arrangement. For that reason, two configurations with a 2MWh and a 1MWh battery, respectively, are presented. Aside from different size batteries, both truck configurations are the same. The small 1MWh battery configuration will achieve the acceleration and gradeability performance of the large battery configuration at similar weights.

Note that in the above weight charts, the curb weight does not include the weight of the driver for which an additional 250 pounds is allowed when computing payload.

Operational Considerations

Before we can understand the economics of operating a Tesla electric truck, it is necessary to think about how these trucks will be used. Two things are key to electric truck economics - How frequently and for how long is the truck charging, and how much does that charging cost the trucking company.

This brings us to the concept of "stage length", that is the distance over which an electric truck in line-haul service can regularly and routinely operate. Variations in trailer weights and in weather conditions necessitate practical stage length less than the "ideal" range of the truck to assure successful operation under adverse conditions. As a result, most of the time, trucks arrive at the charging station with substantial remaining charge. Over time, charging stations will proliferate so that truckers will choose where to recharge, more fully depleting the battery and minimizing total number of recharging stops.

In the economic analysis that follows, we use a stage length equal to 75% of the ideal range at 65MPH and 60,000 pounds GCW.

Charging time is critical for electric trucks. An electric truck with a 2MWh battery, charging from a 15A 120V wall socket will require about two months to fully charge. Even if this truck connects to all the charging bays at a three-charger, six-charging slot SuperCharger, it would take 6 hours to recharge. A "LudicrousCharger" of say 3MW (theoretically capable of recharging a Model S100D in 2 minutes, if the battery could withstand that charging rate) would still need 40 minutes to recharge most of a 2MWh truck battery. Operating at 400 Volts, the charging cable would need to carry 7,500 Amperes. A small crane would be needed to lift the plug and charging cable. While such a charging solution could be built, it still requires 40 minutes or more to recharge, and a station able to charge several trucks at once would require a very robust grid connection and incur spectacular demand charges.

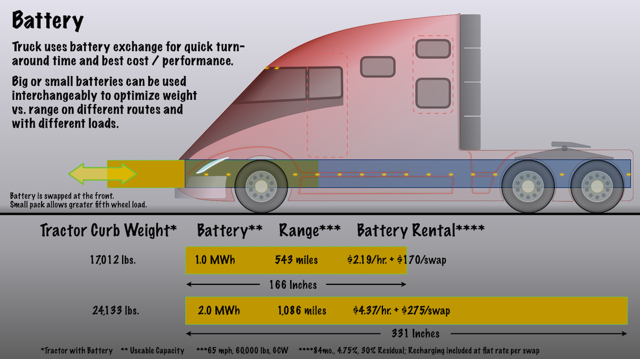

Having looked at several recharging schemes, I concluded that battery swapping is a much more attractive approach for a line-haul electric truck. The envisioned Tesla truck with the battery located within the central box-beam frame allows convenient swapping through the front of the truck without requiring specialized machinery operating from beneath the truck, or large clearance space beside the truck - both significant considerations in determining the size and cost of truck recharging (battery swap) stations.

An important advantage of the battery swap approach is that the swap station operator can choose when to recharge in coming batteries and thus capture the lowest time of day electric rates. This is not possible with a "SuperCharger" solution unless large amounts of grid connected storage is used at the charging station.

Battery swapping also supports flexibility to match battery size in the truck to the load and range requirements of particular routes and loads. Swapping enables an interesting business model wherein the truck operator never owns the battery - making these trucks cheap to initially purchase (battery not included). The operator then rents a battery of desired capacity at an hourly rate that reflects the equivalent leasing of the battery, plus a fixed fee each time the battery is swapped for a fully charged battery. Energy cost is included in the fixed "swap fee".

The battery swap station must finance an inventory of batteries ready to be swapped from the swap fee, while the batteries in trucks are financed by the hourly rental fee. How this business model works with respect to the Tesla truck is illustrated in the following sketch. At any time, the truck operator is paying the battery capital cost (through the hourly rental) for only as much battery as needed for the particular route and load.

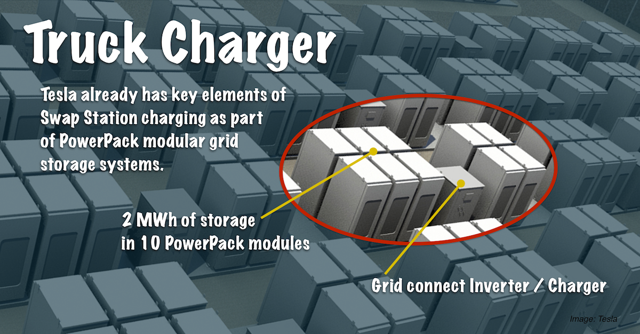

Interestingly, Tesla is already selling modular grid storage systems that are ideally sized to perform charging of these 1MWh and 2MWh battery packs. PowerPack grid storage technology incorporated into truck battery swap stations would even allow stations to use some of their inventory batteries to provide grid stabilization services, generating substantial additional revenue not included in this model.

Of course, when the economics of this model are assessed, both the truck operator and the swap station have to be profitable or the model is not sustainable. This brings us to costs and the fundamental competitiveness or uncompetitiveness of a Tesla electric truck.

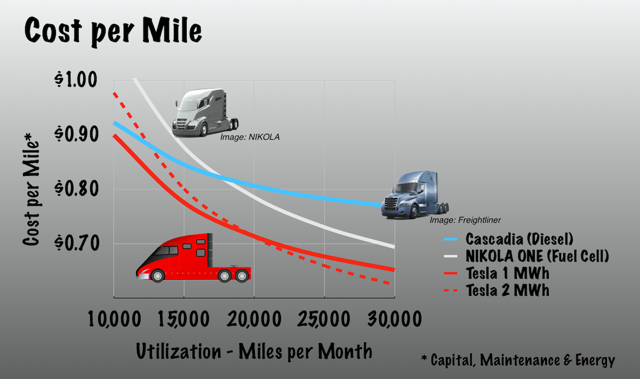

Comparing Costs

The key result from analyzing the Tesla truck, Freightliner truck and NILOLA ONE truck is seen in the following plot of operating cost per mile as a function of utilization. The 1MWh Tesla truck has lower operating cost over the range of utilization rates seen in line-haul trucking. The 2MWh Tesla truck excels at very high utilization rates, and when operated 1,000 miles per day or more (team drivers), is 15 cents a mile cheaper than a diesel truck to own and operate.

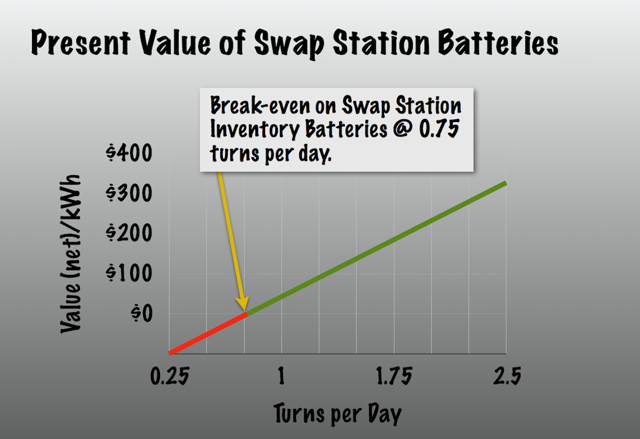

The economic case for swap station operations is as compelling as that for the truck itself. The following chart shows the present value of swap station inventory batteries as a function of the number of swaps each inventory battery makes per day. The model accounts for cost of recharging energy, cost of performing the swaps, and overhead. Profits over seven-year period and the assumption that batteries retain 30% of their cost basis are discounted at 8% to compute the net present value per kWh. This calculation shows that Tesla would see approximately 100% gross margin over battery module cost if batteries are "turned" just 1.3 times per day. And, as stated earlier, no allowance is included for revenue from grid connected storage services such as spinning reserve, frequency stabilization, etc.

The economic case for swap station operations is as compelling as that for the truck itself. The following chart shows the present value of swap station inventory batteries as a function of the number of swaps each inventory battery makes per day. The model accounts for cost of recharging energy, cost of performing the swaps, and overhead. Profits over seven-year period and the assumption that batteries retain 30% of their cost basis are discounted at 8% to compute the net present value per kWh. This calculation shows that Tesla would see approximately 100% gross margin over battery module cost if batteries are "turned" just 1.3 times per day. And, as stated earlier, no allowance is included for revenue from grid connected storage services such as spinning reserve, frequency stabilization, etc. Just as was the case when estimating performance, assumptions were necessarily made when estimating costs. The following table lists the assumptions used. The intent is that these costs and related assumptions apply to the case of a Tesla truck first delivered in mid 2019, two years from now.

Just as was the case when estimating performance, assumptions were necessarily made when estimating costs. The following table lists the assumptions used. The intent is that these costs and related assumptions apply to the case of a Tesla truck first delivered in mid 2019, two years from now.| Cost Element | Value | Description |

| Battery Cost | $100/kWh | Tesla's battery cost at module level |

| Battery Price | $150/kWh | Used for setting battery hourly rental rates |

| Lease Rate | 4.75% | Rate used for converting truck operator costs to per-mile values |

| Lease Term | 84 months | Lease duration for assessing truck operator capital costs |

| Lease Residual | 30% | End of lease residual value |

| Federal truck excise tax rate | 15% | Applicable to purchase price of truck |

| Sales tax rate | 8% | Applicable to sales price + FET |

| Applicable to Swap Station | ||

| Cost to perform battery swap | $40 | Burdened marginal cost of swapping. Same for 1MWh or 2MWh pack |

| Cost of electricity | $0.035/kWh | Cost of electricity for recharging - assumes off-peak average rate across all stations |

| Energy to recharge 1MWh / 2MWh pack | 960 / 1,920 kWh | Assumes 10% useable capacity remaining at turn-in and 90% charging efficiency |

| Charge Station Overhead | $1/kWh/month | Overhead is taken as proportional to the amount of batteries in 'inventory' |

| Discount Rate | 8% | Used to discount station profits |

| Present value breakeven cost | $100/kWh | Cost Swap Station inventory batteries |

| Truck Operator Ownership, Energy & Maintenance Costs | ||

| Diesel Truck | Price $162,500 | Source: Commercial Truck Trader |

| Fuel $0.54/mile | Source: Truck Report | |

| Maint. $0.12/mile | ||

| Tires $0.03/mile | ||

| NIKOLA ONE | Price $385,000 | Base price, no fuel included |

| Fuel $0.36/mile | Estimated as 2/3 diesel | |

| Maint. $0.12/mile | Similar to diesel. This is a fuel cell system + an electric truck | |

| Tires $0.03/mile | ||

| Tesla truck | Price $150,000 | Battery NOT included |

| Fuel: Hourly rental + Swap fee. See figure above. Dist between swaps: 407mi (1MWh) / 814mi (2MWh) | ||

| Maint. $0.07/mile | Simpler than diesel | |

| Tires $0.03/mile | Similar to diesel |

Overall Competitiveness

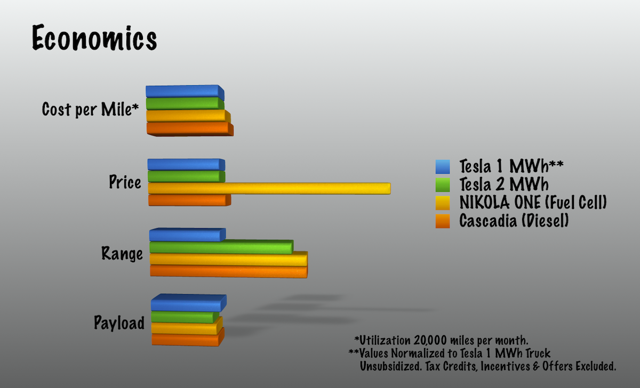

There are four (and perhaps more) areas of cost and performance that matter in line-haul trucks. The following chart compares the Tesla electric truck to both current diesel trucks and potential future fuel cell - electric trucks.

The Tesla electric truck has the lowest cost per mile (operation and ownership) and the lowest acquisition cost. While the Tesla truck likely will fall short in ultimate range, range per charge is sufficient for practical line-haul applications, and fast battery swap recharging largely mitigates any shortcoming. For payload, the Tesla truck is competitive, with the added advantage of being able to tailor the battery size to trade payload against range.

The Tesla electric truck has the lowest cost per mile (operation and ownership) and the lowest acquisition cost. While the Tesla truck likely will fall short in ultimate range, range per charge is sufficient for practical line-haul applications, and fast battery swap recharging largely mitigates any shortcoming. For payload, the Tesla truck is competitive, with the added advantage of being able to tailor the battery size to trade payload against range.

Implications

From the above analysis, it appears Tesla could deliver a semi truck that is competitive both in performance and economically. This does not mean Tesla will necessarily introduce an electric semi truck with the characteristics described. But it does show there is a path by which Tesla could offer a very compelling electric truck. Come September, we will see.

For other companies in the heavy truck business, a compelling Tesla electric truck could be very disruptive. If Tesla achieves a low cost of acquisition and low operating costs as it appears it may be able to, then the highly cost sensitive trucking industry can be expected to switch to Tesla trucks, or to similar offerings from others. How nice Tesla makes the truck look, how quickly the truck accelerates, how fast the truck hauls loads up steep hills will all make news. But how much it costs per mile to own and operate Tesla's truck is what will matter in the end.

The difficulty for established truck makers should Tesla's truck be a success will be similar to the problem legacy ICE car makers are facing with the advent of practical, good performing electric cars. In the case of heavy trucks, however, the shift in market demand - driven largely by economic considerations - could be much more abrupt. This could leave legacy truck makers scrambling for three things: High speed, compact, liquid cooled induction motor drivelines, sufficient cell supply to build lots of trucks with huge batteries, and charging or battery swapping infrastructure to support their electric truck models in service.

All of the things legacy truck makers need to compete in electric line-haul heavy trucks are things Tesla is good at, things where Tesla holds a lead in technology, manufacturing or capacity. And, when it comes to cell supply and electric driveline engineers, carmakers scrambling to enter the electric car arena will be competing for those assets, too.

For Tesla, there will be significant impact from entering the heavy truck business. Tesla building say 10,000 heavy trucks of the kind described would require the equivalent of 60,000 Model 3 motors, inverters and drivelines - something significant but manageable. A much more significant impact would be on the battery side. If the 10,000 Tesla heavy trucks each use the 2MWh battery, and swapping stations average one inventory turn per day, then 4MWh of truck batteries will be needed for each truck (one battery in the truck + one battery in inventory at a swap station). Ten thousand trucks a year on this basis would require 40GWh of additional cell supply. This is more than the entire design capacity of the fully built out Nevada GigaFactory. It is also more cells than Tesla will need to make 500,000 Model 3 cars. No wonder Elon Musk is talking about building a lot more GigaFactories.

Other aspects of Tesla's business that could see impact from a successful entry into heavy trucks include grid storage and SuperChargers. In the operating and business model described, trucks are supported by battery swap stations at trucking "hubs" and along major trucking routes. These swap stations will need charging systems for recharging exchanged batteries, and as pointed out, the inverter/charger equipment Tesla currently uses with their PowerPack product is both nicely sized for charging these big truck batteries, and configured to allow some of the batteries in swap station inventory to be used for grid connected storage applications, increasing station revenue. Standing up swap stations to support 10,000 truck per year production as described above is equivalent to installing 20GWh of grid storage per year! That's a huge increment in Tesla's grid storage business. Of course, if Tesla does stand up a robust heavy truck battery swap infrastructure, there will be the opportunity to sell access to that infrastructure to other truck makers/other trucking operators - though that would require, for logistical reasons, that other truck makers adopt Tesla's physical, electrical, and cooling standards for their batteries.

The bottom line for Tesla is that successful entry to the heavy truck market with an electric truck offers an opportunity to grow the business very significantly. Tesla investors will want to pay close attention in September and assess how well or poorly Tesla's electric truck is likely to compete and whether or not Tesla will disrupt another industry.

The likelihood that Tesla will introduce a compelling heavy truck and start the ball rolling toward widespread use of electric heavy line-haul trucks is one more indicator we are looking at rapidly ramping battery demand. If Tesla initiates disruption of heavy trucks, that is one more huge increment for the battery and battery materials supply chain that is already ramping to support a switch to electric cars and mass deployment of grid storage systems.

I believe there are some interesting opportunities for investors in the battery supply chain. Resource companies in nickel, cobalt, and of course lithium are potential winners. So are some of the specialty companies making things like cell separators and electrolytes. Cell makers are also on the list of companies investors will be looking at. Other analysts will undoubtedly cover the major players and are likely to offer better and deeper understanding of company financials and competitive positions of these companies. But there are also some small players with unusual approaches or technologies that while much riskier offer potentially enormous investor returns.

As the battery and battery materials supply chain stretches with explosively ramping demand, bottlenecks are bound to develop. If investors can find a small company with the solution to a potential battery supply chain bottleneck such a company may be worth a flyer. But let's be perfectly clear, such companies will be very risky investments, and one's chance of losing every dollar invested is probably greater than one's chance of having a 10 bagger or 50 bagger with such a stock. I have recently been looking for these kinds of small companies with potentially silver-bullet solutions and have made small investments in a couple of them. I am going to describe these companies and the rationale that led me to take a flyer on each. I don't think I have necessarily found the "best" companies in the arena, and I'm still looking. Perhaps readers will identify additional candidates in the comments.

The first company that caught my eye is Pure Energy Metals (OTCQB:PEMIF). The company aims to use a solvent extraction process to obtain particularly pure lithium hydroxide from lithium brine deposits without the time, cost and environmental impact associated with the conventional evaporation pond concentration step used by the major lithium brine extraction companies. Pure Energy has secured some lithium claims in Clayton Valley, Nevada adjacent to the existing Albemarle (NYSE:ALB) lithium operation.

Two things about Pure Energy interest me. First, because the process it intends to use can be ramped quickly (no delay of years waiting for brine in evaporation pools to concentrate). So, Pure Energy can (at least in theory) respond more quickly to any choking of lithium supply. Second, because the solvent extraction process produces comparatively pure product, the company may find itself supplying makers of the highest energy density cells, and find its product in particularly high demand.

Pure Energy Metals has a website here with news about the company and links to company financials and other Canadian filings. The Seeking Alpha page for Pure Energy Metals that links from the ticker symbol above also has information on company financials. According to a June 7th filing, the company has exchanged up to 22.5% (warrants fully exercised) of the company for substantial additional lithium claims in Clayton Valley plus an additional $2 million in capital. The company now holds lithium claims essentially boxing-in Albemarle's Clayton Valley lithium deposit.

This strategic move by Pure Energy Metals came at a steep price in terms of dilution and is indicative of one of the risks investors will face should they put money into this stock. Some of the other important risks associated with speculative, micro-cap companies of this kind include becoming illiquid due to disappearing market interest in the company. And, of course, being a comparatively small company ($26.7 million market cap at this writing) with no significant income stream, the company runs a real risk of becoming insolvent.

The second company is Nano One (OTCPK:NNOMF). This company is developing an interesting process for making lithium ion cathode materials. Its process mixes the input materials (for instance cobalt, nickel, aluminum, and lithium in the case of NCA cathode material) in an aqueous solution to form nanoparticles of uniform composition. These nanoparticles are then sintered to produce cathode powder.

There are two advantages to Nano One's process that could respectively open up possible future bottlenecks in supply of lithium hydroxide and potentially enable manufacture of better performing cathode materials and better batteries. The first advantage is that the Nano One process can use either lithium hydroxide or lithium carbonate as feedstock where current processes for nickel containing cathode materials must have lithium hydroxide and cannot use lithium carbonate. This means Nano One's process is a way around supply chain issues that may occur with the refining of lithium carbonate into lithium hydroxide.

The second Nano One process advantage is that it very uniformly distributes cathode constituents within the final cathode powder. This may prove significant as a way to get the highest storage capacity and hence the highest energy density cells. Because the Nano One process can be used for most common lithium cathode materials (NCA, NCM, NMO...), it is likely to be of interest to cathode material and lithium cell manufacturers.

I was able to talk a couple of weeks ago with Dan Blondal, Nano One's CEO and came away with the impression that these are a group of competent folks with a great solution in search of a problem. And, because I believe the right kind of problems may be coming our way in the battery materials supply chain, I think Nano One has a shot to make investors (including me) some money down the line. Here is a talk Dan Blondal gave at the InvestorIntel’s 6th Annual Cleantech & Technology Metals Summit on June 28th.

The Nano One website provides links to its financials and Canadian filings. In addition to the several micro-cap risks discussed with respect to Pure Energy Metals, Nano One has additional risk in that this stock is very thinly traded. Over the last 10 days, average daily volume has been just over 8,000 shares. Should an investor in this company need to exit the stock, it may not be possible to do so over a short time period.

I have no relationship with either Pure Energy Metals or Nano One other than as a (minor) shareholder. I don't think anyone should invest in these companies solely on the basis that I have done so. Nano One in particular is a very small company, is very thinly traded, and investors should appreciate the significant risk associated with this and similar very small public companies.

The reason for presenting my rationale for investing in these small and potentially risky companies is to illustrate the kinds of interesting, though highly speculative opportunities investors may find beyond established players in the battery supply chain. Because the lithium battery supply chain is likely to ramp rapidly over the next few years, I believe an opportunity exists for some (very definitely not all) small, innovative companies in this space.

No comments:

Post a Comment