The Journey for Excellence

It is finally spring in Philadelphia. Yesterday, as I walked the streets on the way to ballet, I saw flowers for the first time in a year. I love spring. It is a time for awakening.

My body is decompressing from travel, but my mind is full of ideas. I have been on the road for the past three weeks speaking at seven events. Travel is both enriching and exhausting. As I walked, I reflected on the many discussions that I have recently had with multiple supply chain leaders on Supply Chain Excellence. Ahead, I have a week of writing. I am busy finalizing a report on the current state of the inventory optimization market, rewriting and updating a report on Sales and Operations technologies, and penning a new report on Supply Chain Centers of Excellence.

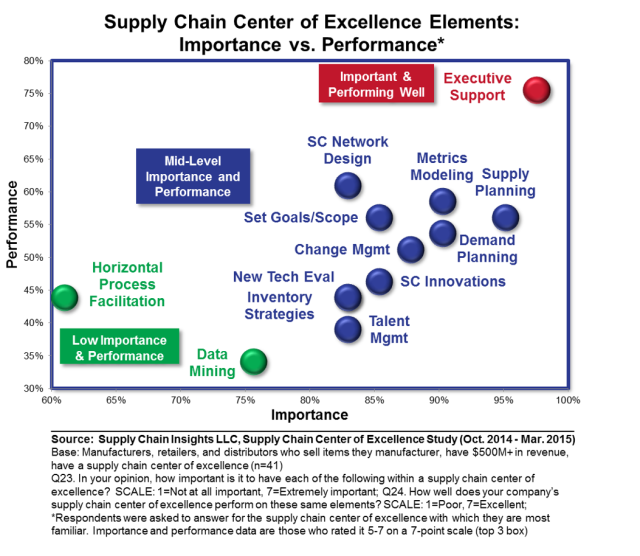

Today, I am deep into the recent research on the Supply Chain Centers of Excellence. We have pulled the data from the field on the Supply Chain Centers of Excellence survey; and to gain insights to finalize my thoughts for the report, I am sharing the data with two groups of supply chain leaders: those that have a center of excellence, and those that do not. Last week I spoke to 26 attendees that had a center of excellence; and this week I will speak to 15 companies that do not have a center of excellence, but are considering the implementation of the concept. I am sharing charts like those in Figure 1.

Figure 1. Center of Excellence Elements

What am I finding?

1) Origin. Most supply chain centers of excellence evolved from a multi-year ERP implementation, or the evolution of a strategy to form a global multinational supply chain.

2) Charter. For most companies, there is confusion on the charter. While the evolution of supply chain excellence is forward-looking and visionary, most have defined the center to focus on expertise or competency. The difference is the assumption that there are ‘supply chain best practices’. The difference? A center of expertise works on the standardization of best practices, while a center of excellence focuses on the improvement of performance. In this world of supply chain practice, where processes are only 30-years old and still evolving, this is a very big difference.

3) Maturity. As shown in Figure 1, the processes are the most mature in the areas of network design. There is also intense focus on the implementation of demand and supply planning. However, the areas of talent development, inventory management, and the implementation of horizontal processes (Sales and Operations Planning, Supplier Development and Corporate Social Responsibility) are less mature.

4) Regional Global Governance. Most centers of excellence struggle with the issues of global governance. To be successful, it is important to answer the question of, “What is the role of the corporate planning team, and what is the role of the region?” Many learn this too late. Answering this early and often is essential to survival in a sea of corporate politics.

5) Supply Chain Excellence Work Is Important. For companies that have a mature Center of Excellence working on horizontal processes and talent development, there is greater alignment and organizational agility. A focus on excellence is quite different than a focus on expertise. I am trying to understand the drivers through my interviews with the leaders. So to get the full scoop look for the report….

No comments:

Post a Comment